[Newly Renovated Old Building] "Shaoyi Hospital" Gets a Fresh Makeover: Boosted in Both Aesthetics and Expertise—The Qichun Campus Redevelopment Project of Sir Run Run Shaw Hospital, Zhejiang University School of Medicine

Category to which: Premium Cases

Category to which: Service Cases

Category to which: After-sales Operation and Maintenance Transformation

In July 2024, the newly renovated operating rooms and central sterile supply department in Building 2 of the Qingchun Campus of Sir Run Run Shaw Hospital, Affiliated to Zhejiang University School of Medicine, were gradually put into operation, significantly easing the hospital’s growing medical workload. The renovation was completed by Wuhan Huakang Century Medical Co., Ltd., marking another milestone in elevating the renowned Shaw Hospital brand on its journey toward excellence—and setting a benchmark for the company’s medical facility renovation projects.

Hospital Details

The Sir Run Run Shaw Hospital, Affiliated to Zhejiang University School of Medicine, was established through a generous donation by Sir Run Run Shaw, a renowned Hong Kong entrepreneur, complemented by matching funds from the Zhejiang Provincial People's Government. As a public, comprehensive Grade III Class A hospital integrating medical care, education, research, and social services, it officially began operations in May 1994. Located at No. 3 Qingchun East Road, Jianggan District, Hangzhou City, Zhejiang Province, the Qingchun Campus was completed in 1994, covering an area of 89.5 mu. It serves as the Third Clinical Medical College of Zhejiang University School of Medicine and also functions as the National General Practice Technology Guidance Center, the Zhejiang Provincial Minimally Invasive Reproductive Technology Guidance Center, the Zhejiang Provincial Corneal Disease Diagnosis and Treatment Technology Guidance Center, and the Zhejiang Provincial Fetal Heart Ultrasound Diagnostic Technology Guidance Center. Over the years, the hospital has earned prestigious accolades such as the National Advanced Collective in the Health System and China’s Best Employer among Medical Institutions.

Project Details

The project primarily involves renovating the following areas: the Sterilization and Supply Center on the 2nd floor of Building 2, the operating rooms on the 3rd floor, and the equipment mezzanine on the 4th floor (M level), encompassing tasks such as interior decoration, air purification, structural reinforcement, and associated electrical and plumbing installations. To ensure the hospital maintains its regular medical operations, the project is being carried out concurrently with ongoing hospital activities—specifically, by dividing construction into distinct floors and zones. This approach minimizes disruption to other functioning patient areas while still delivering a high-quality, timely completion of the renovation tasks.

Renovation Requirements

1. Renovate and integrate the second-floor hemodialysis unit into the Central Sterile Supply Department, expanding the overall usable area of the CSSD to ensure it meets the hospital’s sterilization supply needs and regulatory requirements.

2. Conduct a partial renovation of the three operating rooms, replacing the 15 operating rooms' embedded electric doors with externally mounted electric doors. Additionally, upgrade the air conditioning control panels in these 15 operating rooms and in Operating Room #28 to integrated 27-inch LCD touch-screen central control panels.

3. The original four-story ward building will be converted into an operating suite, featuring 13 Class III operating rooms and 2 non-laminar flow transplant rooms, along with supporting Class IV clean ancillary facilities and the corresponding office and living areas.

4. Upgrade the air conditioning units in the M-layer equipment mezzanine, construct a new air conditioning machine room, and install additional UPS systems and busbars to ensure the seamless operation of the operating rooms.

5. Other requirements: Installation of additional heating and cooling equipment on the 5th-floor roof, along with noise-reduction measures; addition of a new outdoor No. 9 cleaning staircase with connecting corridor for Building 2, plus renovation of the existing No. 7 waste elevator to extend it up to the 4th floor.

Difficulty Analysis

1. The project involves the intersection of multiple systems and disciplines, encompassing a wide range of tasks such as demolition, new construction, elevators, fire protection, interior decoration, structural reinforcement, steelwork, electrical and plumbing systems, HVAC, medical gas installations, and more—placing extremely high demands on the client’s expertise, construction qualifications, and project experience.

2. As a renowned Grade-III hospital, the client organization has high demands, stringent standards, and well-defined processes. Therefore, during the construction phase, it requires close coordination among all departments and disciplines to ensure seamless collaboration, along with robust on-site construction management, material control, environmental oversight, and quality assurance.

3. The project involves several areas that require simultaneous use and construction: The renovation of the 2nd-floor Sterilization Supply Center affects both the existing Sterilization Supply Center and the Hemodialysis Ward, so operations in other areas must not be disrupted during the work. Additionally, the equipment mezzanine on the M floor primarily serves the 3rd-floor Operating Department; therefore, construction activities there must ensure the department can continue functioning normally. Meanwhile, the renovation of the operating rooms on the 4th-floor involves extensive demolition work, which could easily impact the functionality of other floors.

4. The floor-to-ceiling height in the 4th-floor ward area and on the M level is relatively low, resulting in tight construction spaces and making integrated piping work extremely challenging.

5. The project has a tight schedule and requires aggressive progress management. To ensure smooth transitions between different disciplines and work processes, it’s essential to maintain a high level of control over key project milestones.

Construction Plan

1. Co-create with users and ensure thorough communication to clearly define requirements

During the drawing verification phase, technical staff conduct on-site surveys, first meticulously reviewing and confirming each blueprint individually. In the second stage, guided by the principle of "customer-centricity and collaborative co-creation with users," the project team engages in in-depth discussions with the department to gather their renovation requirements. The team then refines and validates the proposed renovation plan multiple times, refining details down to the fourth-level process. This ensures precise planning for critical elements such as water and electrical outlet locations, network socket placements, sink positions, equipment layout orientations, as well as decisions on surface material colors and accessory specifications. Ultimately, this leads to the creation of detailed construction drawings and visual renderings, which are subsequently submitted for a second round of confirmation with the department. This rigorous validation process guarantees the accuracy and completeness of the blueprints, ensuring both a consistent aesthetic alignment between existing and newly renovated areas—and meeting the department’s unique functional needs. Thanks to this thorough and well-coordinated communication upfront, the project minimizes rework, boosts construction efficiency, and helps keep costs under control.

2. Leverage efficient coordination to align and engage all parties simultaneously.

The renovation project involves multiple departments and specialties, so throughout the construction process, the project team has fully leveraged its ability to collaborate efficiently. They’ve maintained open communication and coordination with various hospital departments, including logistics, infrastructure, infection control, the design institute, and the supervision team. Together, these teams have established a joint management mechanism, jointly discussing and finalizing a practical renovation plan and implementation schedule—ensuring the project progresses smoothly and effectively.

At the same time, the project team has placed strong emphasis on construction efficiency, holding regular alignment meetings with relevant hospital departments to share updates on progress and address any challenges. By dynamically adjusting the construction plan as needed, they’re ensuring that the project stays on track, enabling early completion and maximizing both economic and social benefits.

3. Standardize construction management and operate while renovating

① Personnel Management

Huakang Medical has established a dedicated project team, created comprehensive personnel information files for construction workers, and standardized their uniforms. Additionally, the company regularly conducts training sessions for all staff on safety regulations, fire safety protocols, and production management practices, ensuring that safety awareness is consistently reinforced. A rigorous system of random inspections and routine patrols has been implemented to systematically evaluate and assess construction workers' performance.

② Streamlined Management

Since the construction area is located within an operational building, it’s crucial to segregate construction worker and material flow routes from patient and medical staff pathways as much as possible, ensuring effective infection control. Based on the project’s specific conditions, the project team has designated the soiled materials elevator as the primary means for construction personnel access and material transport, while carefully protecting the elevator car to prevent its use by patients and ensuring it avoids other operational areas. Additionally, elevators serving the construction zone have been temporarily disabled from direct access, with clear safety signage installed to prevent unauthorized personnel from entering the area.

③ Environmental Management

The project employs a build-and-operate model, so even before entering the site, the project team assigned dedicated personnel to assist medical staff in comforting patients and gaining their understanding.

To minimize noise and dust disruptions to patients and staff on other floors and in surrounding areas during construction, the project team has implemented strict guidelines for scheduling work hours—specifically, staggering construction activities. Tasks that generate significant noise must be carefully timed to avoid coinciding with patient and staff rest periods. Additionally, construction zones will be fully enclosed with barriers, and all construction waste will be removed daily to ensure a "dust-free construction site." Since transporting materials often requires long-term use of hallways, elevators, and other critical pathways, these activities are typically scheduled during nighttime hours to prevent any interference with patients' and staff members' normal routines.

④ Quality Management

To ensure construction quality and efficiency, the project adopts a "model room first" approach. First, a surgical suite model room is created to visually showcase key elements such as space layout, equipment placement, and decorative finishes. Only after the model room passes inspection does the project team proceed with full-scale construction, effectively preventing schedule delays caused by costly rework due to quality issues.

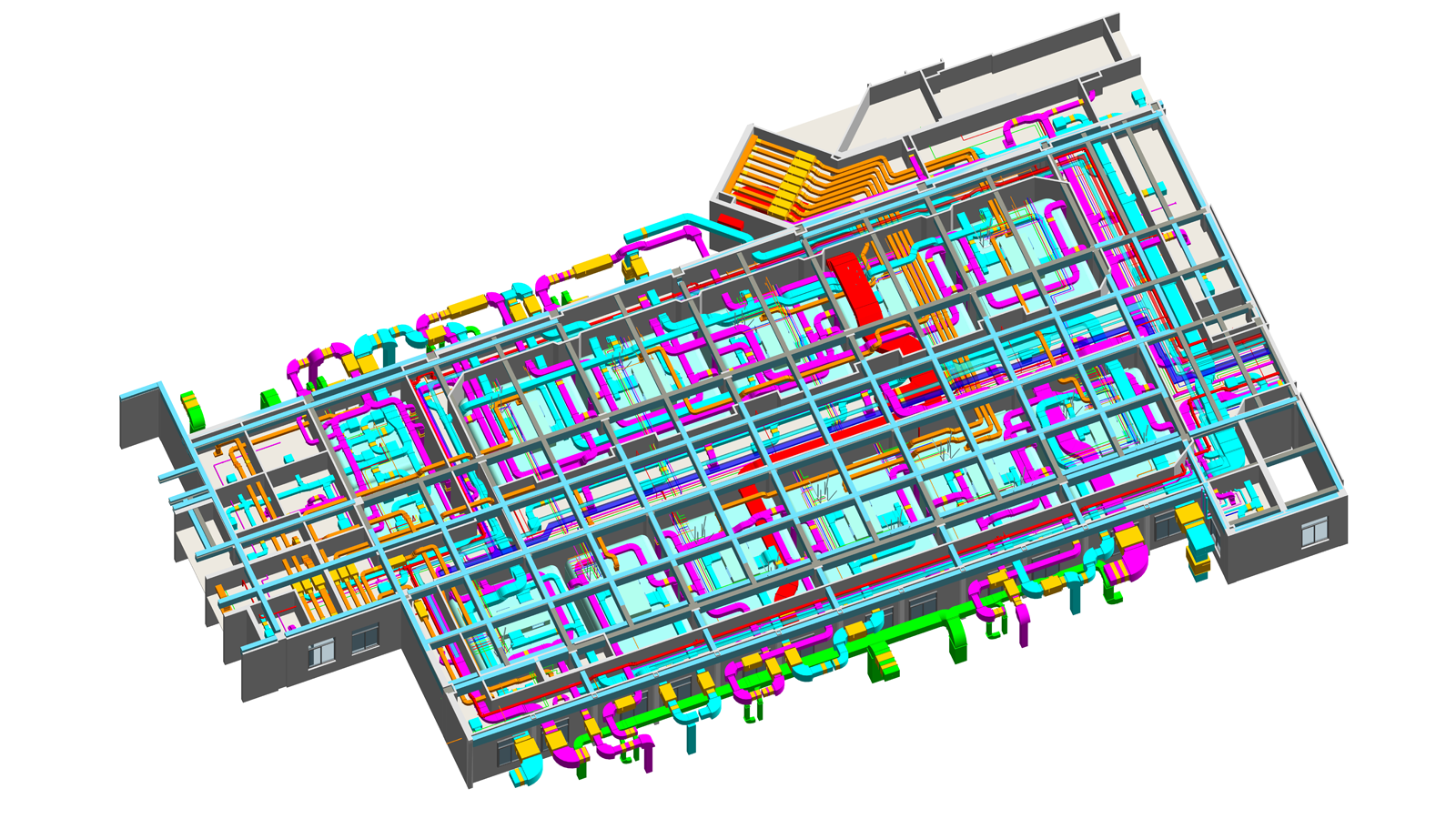

4. Application of BIM technology to tackle spatial challenges

The building housing the project is nearly 20 years old, with the original patient ward area and M-level boasting relatively low ceiling heights. Additionally, the existing structural design features north-south sloping beams—lower on the sides and higher in the center—resulting in a complex layout for mechanical and electrical systems. The operating department’s equipment room is situated in the side mezzanines, forcing all utility lines to traverse the corridors via the lower beams. Meanwhile, the clean corridor is cluttered with an excessive number of ducts, cable trays, fire protection systems, sprinklers, and other piping, significantly detracting from both the space’s aesthetic appeal and operational efficiency.

The Huakang Medical BIM team has moved into the project office to address site-specific challenges. Leveraging the BIM system, they’ve developed a comprehensive spatial modeling and pipeline layout plan tailored to the project conditions.

First, they optimized the design of the ductwork by re-routing some ducts from above the corridors directly into the operating rooms, significantly reducing clutter and minimizing cross-overs in the clean corridors.

Second, for larger-diameter ducts that couldn’t be arranged directly, the team implemented alternative solutions—such as using tapered sections and adjusting routing paths—to avoid overlapping areas altogether.

Finally, the team conducted rigorous pipeline clash tests to validate the proposed layout, ensuring seamless implementation and paving the way for the smooth progression of the project.

Transformation Results

1. Rationally zone areas to fully unlock spatial value

After the project was revamped, the usage area of the Central Sterile Supply Department was expanded, with clear distinctions now made between the decontamination zone, inspection, packaging, and sterilization area, the sterile supply storage area, as well as ancillary rooms and office spaces. Additionally, the flow lines for contaminated waste, clean materials, and medical staff were meticulously redesigned. The fourth-floor wards were transformed into an operating department, adding multiple new operating rooms, clean ancillary rooms, and dedicated office and living areas. This reorganization refined the functional zoning, ensuring efficient use of the limited floor space while optimizing overall functionality. As a result, the hospital’s treatment capacity has been significantly enhanced, enabling it to better meet growing healthcare demands.

2. Hardware upgrades to enhance the overall healthcare standard

This renovation was carried out in line with the hospital's long-term development plan. Specifically, the hospital upgraded the information panel in the 3rd-floor operating department—from a mechanical system to an intelligent, touch-enabled LCD display—making it more convenient for use during surgeries. Additionally, the air conditioning units were updated, and new heating and cooling equipment was added to better meet the hospital’s operational environmental needs. These comprehensive upgrades not only enhance the hospital’s core medical functions but also align more closely with today’s demand for creating smart, high-efficiency healthcare facilities.

3. Environmental Refresh: Enhancing the Patient and Doctor Experience

The renovated operating room and office areas have been completely transformed—spacious, bright, and inviting. During the renovation, soft, clean colors were carefully selected, and highly durable, stain-resistant finishing materials were used to create an indoor environment that seamlessly blends functionality with thoughtful design. This approach not only provides patients with a warm, healing space but also fosters an inspiring and supportive work atmosphere for healthcare professionals, enhancing their overall experience and satisfaction.

4. Blending the old with the new, carrying forward the cultural DNA of "Shao Medicine"

Hospital renovations go beyond simply expanding and upgrading the hospital's physical infrastructure—they also embody the continuation and preservation of the hospital’s core cultural values. During the interior remodeling project, the team carefully preserved the building’s original architectural character, seamlessly integrating the new interior design with the existing façade to highlight the unique cultural identity of the "Shao Medical" brand. Moreover, by thoughtfully repurposing and reusing materials where possible, the project minimized unnecessary waste, aligning perfectly with sustainable, low-carbon, and eco-friendly construction principles.

Against the backdrop of an impending wave of reforms sweeping through public hospitals, in-place upgrades and renovations have become an essential path for many established hospitals and hospital campuses as they look to shape their future. The renovation project at the Qingchun Campus of Sir Run Run Shaw Hospital, Affiliated to Zhejiang University School of Medicine, will help consolidate medical resources, strengthen the hospital’s overall clinical capabilities, and pave the way for expanding the renowned "Shao Yi" brand across Hangzhou and surrounding regions. As a leader in the industry driven by core strengths such as expertise, quality, and innovation, Huakang Medical remains committed to focusing on hospital upgrades and transformations, actively contributing to the enhancement and modernization of high-quality healthcare resources.

Latest case