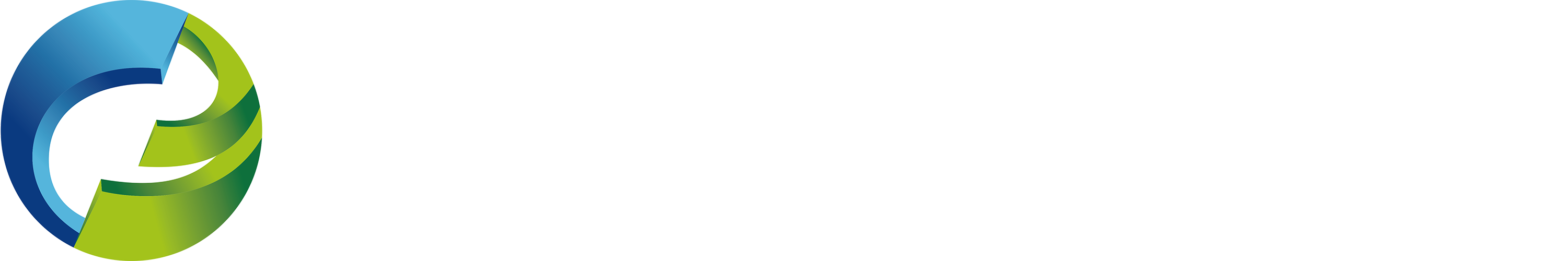

[Laboratory] Serving Industry Entities, Building the Sci-Tech Innovation "Qingyuan Model" — Qingyuan Innovation Laboratory's Renovation Project for Experimental Building No. 2

Focusing on industrialized applications, the chemical laboratory operates with "efficiency at its core, safety as the foundation, and commercialization as the ultimate goal." Huakang Cleanroom has seamlessly integrated industrialization principles into its lab layout planning, safety management, and eco-friendly, energy-efficient operations. By employing a systematic design that spans three spatial dimensions—building, floor, and room—it has established a comprehensive innovation platform specifically tailored to support the entire chain—from applied research and technology development to results transformation and eventual industrialization. This forward-thinking approach elevates the lab from a conventional scientific research facility into a dynamic technology commercialization accelerator, propelling the petrochemical industry toward higher-value segments of the global value chain—and providing tangible support for bolstering the nation’s strategic scientific and technological capabilities.

The experimental building boasts a unique layout that seamlessly integrates north-south-oriented laboratory clusters with east-west connecting corridors, forming a three-dimensional "回" (hui)-shaped research network anchored by a circular circulation design—thus enhancing the efficiency of scientific research activities. At the heart of the vertical transportation system, four staircases and two elevators are symmetrically arranged at the building’s four corners, creating a transport network aligned with the "golden section." This groundbreaking configuration not only establishes an efficient framework for research operations but also ensures smooth logistics for moving large-scale equipment, while simultaneously facilitating emergency evacuations and ensuring the safe and rapid movement of personnel during critical situations.

The laboratory boasts a flexible, modular design with预留 expansion space, allowing it to efficiently adapt to evolving research needs and increasing industry demands by enabling rapid adjustments to the spatial layout.

A Panoramic View of the Qingyuan Innovation Lab

The laboratory headquarters and research center are located in the Quanzhou Port Petrochemical Science & Education Park (Fuzhou University Quanzhou Science & Education Park). The project boasts a total investment of approximately 3.1 billion yuan and features comprehensive infrastructure, including laboratory buildings, teaching facilities, office spaces, and talent apartments. Spanning a total area of 140,000 square meters—of which 57,000 square meters are dedicated to cutting-edge research laboratories—the facility aims to establish itself as a premier hub for technological innovation, a nurturing ground for talent development, and a thriving base for industrial incubation, all while serving as a regional and global benchmark for scientific advancement.

Qingyuan Innovation Lab Building 2

[Huakang Cleanroom Construction Scope]

Construction Scope: Qingyuan Innovation Laboratory Building No. 2

Building area: 7,344 square meters, with a total of 5 floors

Construction includes: a battery materials characterization lab, a photocatalytic water-splitting lab, a pilot-scale amplification lab, and a Class 100 cleanroom lab, among others.

Engineering categories: Decorative finishing, electrical systems, ventilation, air conditioning, low-voltage systems, plumbing and drainage, automation control, centralized gas supply, and more.

Service Focus: Research in Next-Generation Energy Storage Batteries

Project positioning: To be developed into a world-class innovation hub integrating "research, talent, and industry."

Focusing on industrialized applications, the chemical laboratory operates with "efficiency at its core, safety as the foundation, and commercialization as the ultimate goal." Huakang Cleanroom has integrated industrialization principles into its lab layout planning, safety management, and green, energy-efficient operations. Through a systematic design that spans three spatial dimensions—building, floor, and room—it has created a comprehensive innovation platform tailored to seamlessly support the entire chain: from applied research and technology development to成果转化 (results transformation) and eventual industrialization. This approach transforms the lab from a mere scientific research facility into a powerful technology commercialization accelerator, driving the petrochemical industry toward higher-value segments of the global value chain—and providing tangible support for strengthening the nation’s strategic scientific and technological capabilities.

1. Industry-driven: Reimagining the "Functional Matrix" of Research Efficiency

Building 2 is a crucial supporting facility for the Qingyuan Innovation Lab, complementing the functions of surrounding lab buildings while collectively serving five key R&D areas within the petrochemical industry: "Catalysis Science and Technology, Synthetic Materials, Fine Chemicals, Environmental Protection & Safety Technologies, and Process & Product Engineering." It also supports diverse research teams working across these fields. Huakang Cleanroom has focused on designing an overall layout that ensures both functionality and efficiency, aiming to establish the building as a central engine driving breakthroughs in petrochemical technologies that have long been considered bottlenecks—and as a vital link in optimizing and upgrading the entire industry chain.

① Vertical Functional Integration

Advanced Electrolyte Research Lab

Pilot-Scale Amplification Laboratory

Traditional laboratory layouts often create a disconnect between R&D and industrial needs. At the same time, Huakang Cleanroom has strategically designed the functional layout of Building 2 with a strong focus on "industrial applications." By aligning the space planning with the key research areas of the building—specifically, next-generation energy storage batteries—their design meticulously organizes zones based on experimental workflows and functional requirements. The ground floor features a battery performance testing lab, an advanced electrolyte research facility, and a pilot-scale battery assembly room. The middle level houses synthesis labs, pilot-scale amplification labs, and a Class-1000 cleanroom. Meanwhile, the top floor is dedicated to bio-materials R&D labs and electrochemical synthesis facilities. This thoughtful arrangement establishes a seamless vertical workflow—from experimental research to pilot-scale production scaling—directly addressing industry needs such as technology validation, process optimization, and preparation for mass manufacturing.

The lab's "U"-shaped corridor

The experimental building features a unique layout that combines north-south-oriented laboratory clusters with east-west connecting corridors, creating a "回" (hui)-shaped, three-dimensional research network through a circular circulation design—enhancing the efficiency of scientific research activities. Within the vertical transportation system, four staircases and two elevators are symmetrically arranged at the building’s four corners, forming a "golden section"-aligned transport network. This innovative setup not only provides an efficient framework for research operations but also ensures smooth logistics for transporting large-scale equipment, while simultaneously supporting emergency evacuations and personnel movement during critical situations.

② Planar Collaboration Network

To ensure the continuity of research activities and strengthen collaborative innovation among industry, academia, and research institutions, Huakang Cleanroom has adopted a tiered, ring-shaped layout. Each floor features dedicated zones for laboratories, office spaces, and public areas, enabling precise allocation of research functions.

Materials Intelligent Manufacturing Synthesis Lab

Office area

The core experimental area is located at the geometric center of the floor, with experimental content on each floor carefully divided according to the linear flow sequence of experiments and the gradient of pollutant loads. The experimental area is strategically situated adjacent to the instrument analysis zone, the comprehensive reagent library, the pharmaceutical storage room, and the drug analysis lab, enabling efficient collaboration while minimizing sample transport distances.

The office areas and other ancillary facilities are located in the peripheral zones, facilitating easy communication and collaboration while minimizing disruptions to experimental activities. This setup provides a research environment that fosters both independent work and close interdisciplinary cooperation for PI-led scientific teams—teams spearheaded by academicians and nationally recognized experts—in industry, academia, and research partnerships.

③ Local Flexible Adaptation

The laboratory features a flexible, modular design with预留 expansion space, enabling it to efficiently adapt to evolving research needs and growing industry demands by allowing rapid adjustments to the spatial layout.

Photolysis of Water Laboratory

High-Pressure Laboratory

► Cleverly designed transparent glass partitions separate spaces within the electrocatalysis room, water-splitting lab, high-pressure laboratory, and other experimental areas, each equipped with its own independent air conditioning system. These self-contained operational units not only meet the specific environmental requirements of various experiments but also enable flexible use of space, creating personalized experimental setups tailored to researchers' needs.

Thousand-Level Laboratory

►The Class 1000 laboratory includes a preparation room, changing room, buffer zone, air shower room, and experimental lab. It features a scientifically designed functional layout that clearly separates non-clean areas, buffer zones, and clean areas, ensuring an integrated workflow tailored to the precise needs of advanced manufacturing experiments while maintaining the accuracy and reliability of your research.

2. Smart Operations & Maintenance: Building a "Security Fortress" with All-Encompassing Sensing Capabilities

Safety is the lifeline of chemical research and development, as well as a critical prerequisite for industrialization. Adhering to the design principles of "precise control, safety protection, and energy efficiency," Huakang Clean integrates its safety systems seamlessly with intelligent operations and maintenance. This approach not only ensures the safety of personnel, instruments, and experimental data accuracy but also reduces energy consumption and boosts research efficiency. Ultimately, it provides laboratories with a comprehensive, lifecycle-spanning, intelligent management solution that accelerates the efficient transition of scientific discoveries into practical industrial applications.

① Decentralized control, centralized management

Addressing the operational and maintenance challenges in collaborative R&D involving multiple stakeholders, Huakang Clean focuses on safety as its core, developing an intelligent, centralized control system for laboratories. The system features a multi-module collaboration and hierarchical management architecture, integrating functions such as equipment operation management, environmental safety monitoring, real-time tracking of experimental processes, and rapid response to emergency incidents—ensuring buildings achieve optimal energy efficiency while significantly boosting management effectiveness.

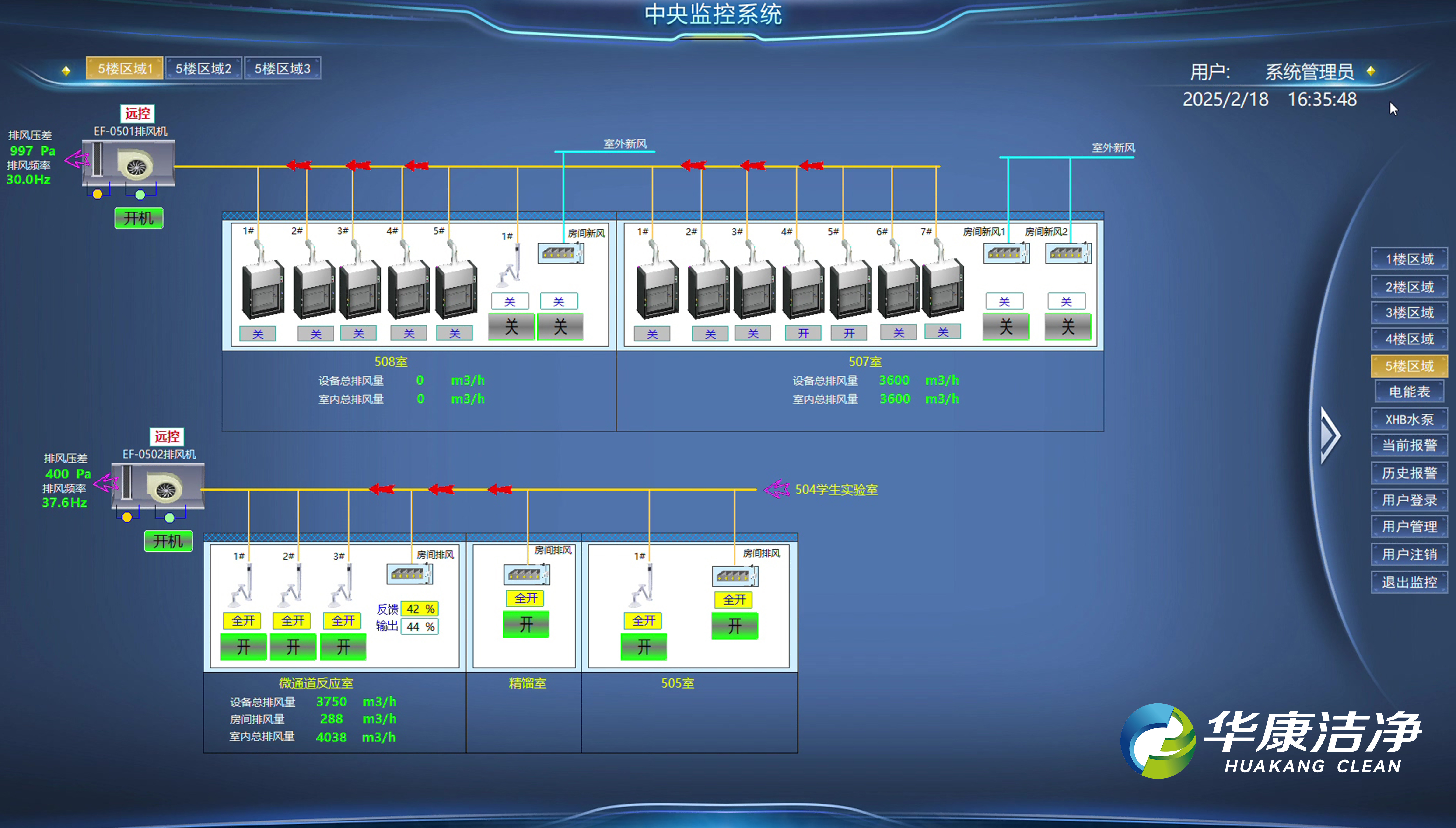

Single Room — Environmental Monitoring System

Corridor — Central Monitoring System for the Laboratory

Building Complex – Central Monitoring System

The system employs a "decentralized control + centralized management" model, seamlessly integrating intelligent macro-resource scheduling with precise micro-environmental control. Each laboratory room is equipped with its own independent environmental monitoring system, ensuring the stability and continuity of individual experimental environments. Meanwhile, data from each room is centrally aggregated and displayed on a visualized operations dashboard located at the corridor entrance on the corresponding floor, enabling facility managers to make swift adjustments. Additionally, environmental data from all lab rooms across the building’s five floors is unifiedly fed into the central monitoring system, allowing for coordinated, cross-regional resource allocation. This "three-tier" environmental monitoring framework—spanning "room-floor-building"—enables real-time tracking of laboratory environmental parameters and equipment status, empowering researchers and administrators to achieve smart, tiered, and region-specific operations and comprehensive process control, thereby ensuring the smooth execution of various science and innovation activities.

② Specialized design, customized solutions

As the "dual-core driver" of safety systems in chemical laboratories, ventilation and gas systems have evolved beyond their traditional role as mere "supporting infrastructure"—instead, they now deeply integrate into critical aspects such as experimental efficiency, data reliability, and even industrial-scale adaptability. Leveraging both cutting-edge research safety needs and stringent industry implementation standards, Huakang Cleanroom delivers tailored, intelligent solutions that empower scientific excellence and drive practical, real-world applications.

Intelligent Control System for Fume Hoods

Pilot-Scale Synthesis Laboratory

► Intelligent Design for Ventilation System Control

The laboratory fume hood control system uses a multi-dimensional sensor matrix to continuously monitor environmental parameters such as gas concentration and air pressure within the lab in real time. This enables dynamic, precise adjustments of ventilation levels, door positioning, and airflow patterns, creating a fully closed-loop, intelligent ecosystem that integrates monitoring, decision-making, and execution. Additionally, the system features smart alarm and fault-diagnosis capabilities, while also providing real-time recording and analysis of usage data—ensuring the safety of the experimental environment, personnel, and equipment, while enhancing the convenience and flexibility of lab management and maintenance.

Additionally, the fume hood is equipped with a human presence detection system that automatically adjusts the face velocity setting when no one is present, switching to a low-power mode. This ensures efficient removal of hazardous gases while significantly reducing energy consumption and operational costs.

Gas Monitoring and Alarm System

Battery Materials Characterization Lab

► Gas Monitoring and Alarm System Design

To ensure a continuous and safe supply of experimental gases, the laboratory is equipped with a gas monitoring and alarm system. The lab features detectors for flammable gases and oxygen concentration, accurately measuring gas levels indoors and triggering audible and visual alarms. Outside the lab corridors, an intelligent gas alarm controller is installed to receive real-time data from each laboratory. If a gas leak is detected, the system automatically activates the ventilation system and simultaneously closes the relevant valves, creating a fully responsive closed-loop mechanism. Additionally, the system is connected to a cloud platform, enabling remote monitoring via mobile devices, computers, and other terminals—making it easier than ever to manage safety effectively.

The No. 2 Experimental Building of Qingyuan Innovation Lab, constructed by Huakang Clean, is a landmark achievement in building an integrated sci-tech innovation platform focused on "research innovation, technology transfer, and industry incubation," aligning with the nation's strategic development plan. The project's successful implementation and operation will significantly enhance the lab's ability to commercialize scientific and technological breakthroughs, break through foreign technology monopolies, and set a new benchmark for fostering deeper integration between the innovation chain and industrial chain in the petrochemical sector.

Latest case